Welcome to 5-Axis CNC Machining

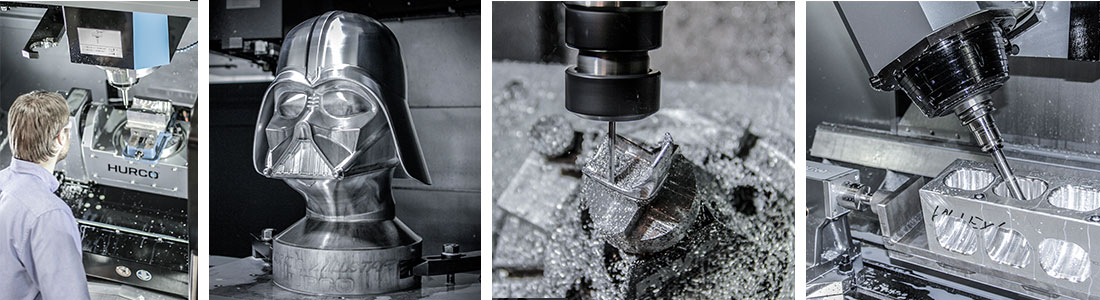

Hurco created this website based on input from customers, application engineers, and sales representatives, who wanted all of the expertise regarding 5-axis and 5-sided machining in one place. We have dedicated an entire team to answer your 5-axis / 5-sided CNC machining questions.

We save 40 minutes per piece in cycle time alone and easily save an hour and 10 minutes total.

Read more…

What is 5-Axis?

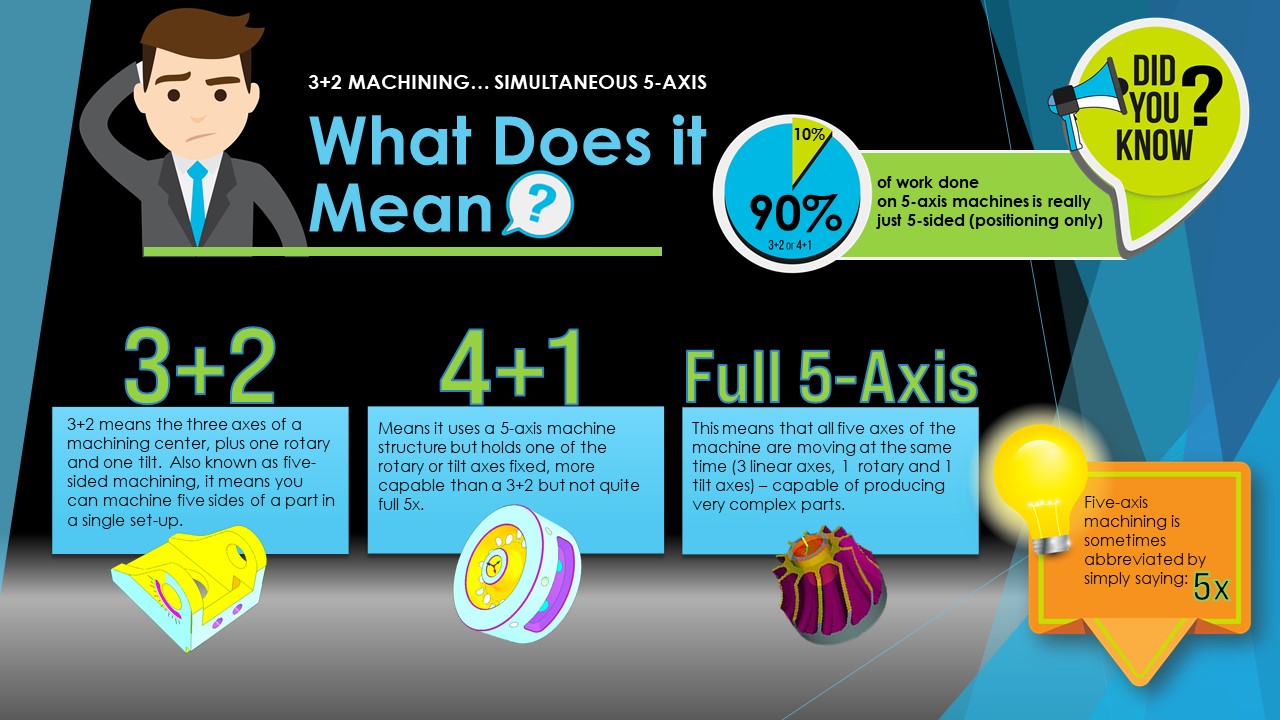

When someone uses the term “5-axis” they are typically referring to the ability of a CNC machine to move a part or a tool on five different CNC axes at the same time. 3-axis machining centers move a part in two directions (X and Y), and the tool moves up and down (Z). 5-axis CNC machining centers can rotate on two additional rotary axes (A and B), which help the cutting tool approach the part from all directions.

Webinar Video

Business Case

Why 5-Axis?

5-Axis CNC

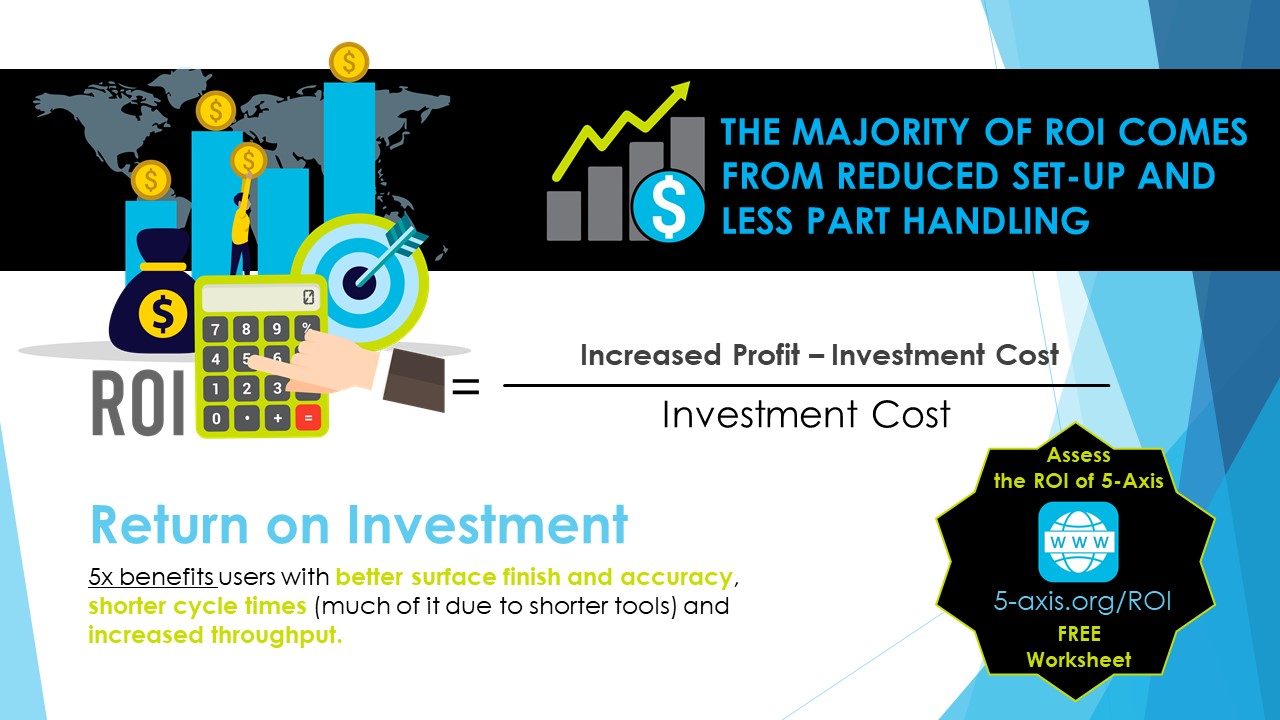

5-Axis CNC ROI Calculator

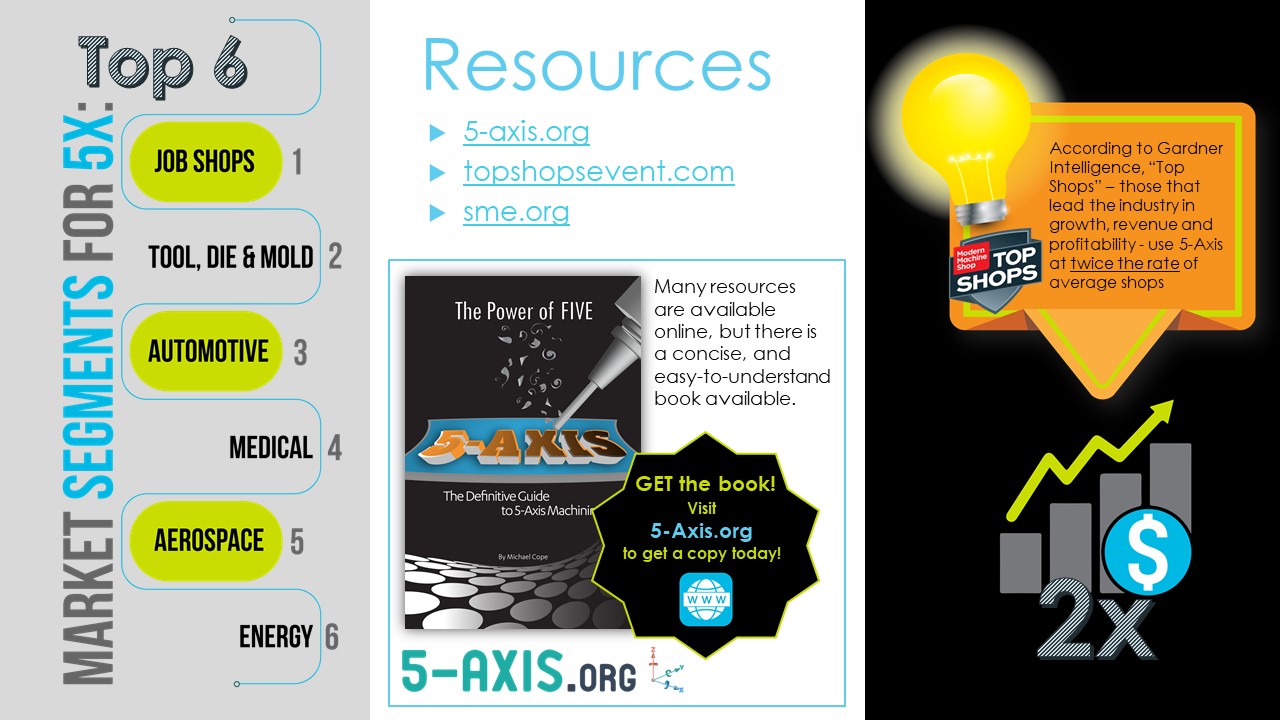

With a 5 axis CNC machine, you can reduce setup time and increase accuracy on each part. You also expand your machine shop’s capability for more work. Often, there seems to be confusion due to the term “5-axis” machining center. Shops think they don’t have 5-axis work. Every shop has work that would benefit from a 5-axis CNC machine because a 5-axis machining center facilitates 5-sided machining.

Click the button below to download a simple worksheet that helps you assess the return on investment of 5-axis.

5-Axis CNC Book Available

About the Book:

According to Mike, author of the CNC book (The Power of FIVE), “I’ve always seen myself as a machinist first and wrote this book with the intention of educating CNC machinists and shop owners on the value of 5-axis machining because I truly believe it is the future of our industry and the most efficient way to produce parts. Making the transition to 5-sided machining on a 5-axis CNC machine solves many of the problems so many shops face: finding qualified machinists (the skills gap), excessive setup costs due to inefficiency, and reacting to pressure from customers, both pricing pressure and delivery pressure.

According to Mike, author of the CNC book (The Power of FIVE), “I’ve always seen myself as a machinist first and wrote this book with the intention of educating CNC machinists and shop owners on the value of 5-axis machining because I truly believe it is the future of our industry and the most efficient way to produce parts. Making the transition to 5-sided machining on a 5-axis CNC machine solves many of the problems so many shops face: finding qualified machinists (the skills gap), excessive setup costs due to inefficiency, and reacting to pressure from customers, both pricing pressure and delivery pressure.

“To be blunt, adding a fifth axis saves time and money. Since time is money in our industry, 5-axis makes each part more profitable. It offsets the skills gap issue because you have more machining capabilities with fewer machines, reducing the need for finding and hiring more skilled employees. The technology makes the process more efficient, so you will increase your productivity because you’re not wasting time flipping parts because you have a single setup. And you can react to pressure from your customers because you can switch from one job to another quickly and efficiently. Basically, you can do more with less if you select the right 5-axis CNC machine.”